Conduit Spacer

Conduit Pipe Spacer

Although Conduit pipe spacers play a small part in the installation process of a HDPE or PVC pipe, the part they play is an important one.

Also known as Conduit Spacers, they’re able to improve a pipe’s performance, reliability, and life-cycle. In addition, duct pipe spacers ensure accurate alignment, provide support, and reduce pipe installation time.

Why You Should Use Tecafine Conduit Spacers

When you need to install a HDPE or PVC Conduit pipe, you’ll need to separate them as per trench or duct bank drawing. For this, you’ll have two options, cement blocks, metal frames or Tecafine Conduit Spacer. Unlike cement blocks or metal frames, Tecafine Conduit Pipe Spacer can provide a number of benefits.

Product Introduction

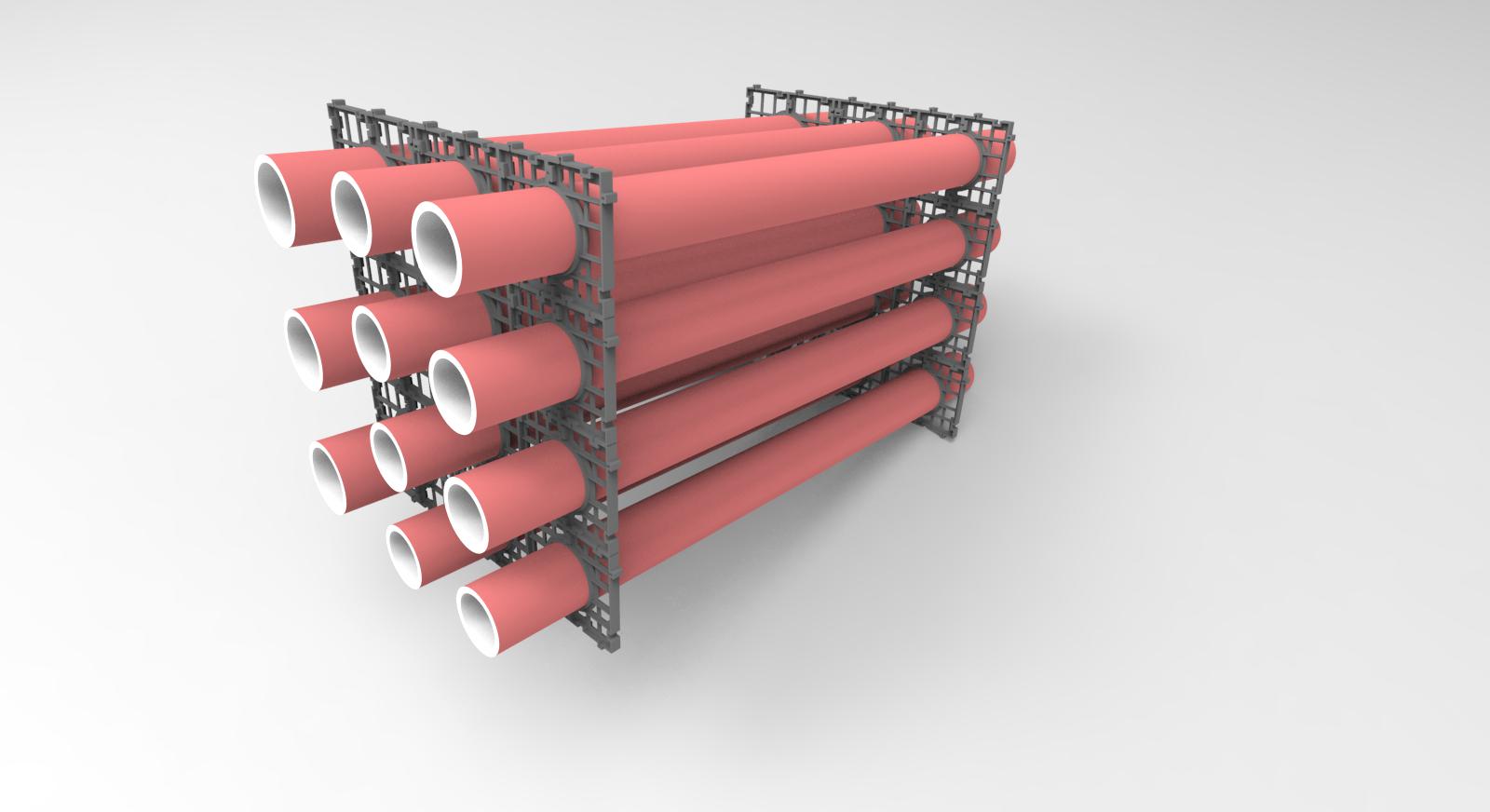

Tecafine has range of Patented Conduit and Duct Pipe Spacers to provide cost effective means to ensure Conduit of varying sizes and configuration can be laid within the Conduit Trench with confidence and that a consistent approved separation of conduits will be maintained. Conduit Spacers are design to temporarily hold the Conduit in place until the trench is back filled.

Repair

Cemented or Metal spacers fill the empty space between various pipes by separating them. After installation, it can make performing repairs on the pipe difficult. For example, if a repair needs to be made, cement blocks will be too heavy to move and metal spacers would have got corroded. Once the repair is done, heavy cement block will have to be placed at same spot. It is also possible to get cracks in Cement blocks due to wet sand or earthly pressure.

With Tecafine Pipe spacers, there will be no corrosion and weather effect. Our Conduit Spacer will keep the pipe centered and secured underground. This means that repairs can be done more efficiently.

Costs

One of the biggest benefits that come with using Tecafine Duct Pipe spacers is the opportunity to lower installation and maintenance costs. Cement Blocks and Metal Spacer are not only expensive, but it requires extremely intensive labor and can act as an electrolyte, inviting unwanted current to the pipe. Tecafine Conduit Pipe spacers, however, eliminate the need of Insulation. This results in efficient installation, repair, and replacement.

Pipe Integrity

When Tecafine Conduit Pipe spacers are installed on a carrier pipe, they provide protection to the pipe in a number of ways including:

- · Uniform support for the weight of the pipe

- · Electrical Insulation

- · Corrosion Protection

- · Keeping various diameter pipes separate

Tecafine Duct Pipe Spacer Is Your One-Stop-Shop For Any Type Of Pipe Spacers

Our team works hard to provide our customers with the best products and services available in the industry. We offer a wide range of Piping and Pipe Spacer solutions through Customized and Standard Pipe Spacer that can be customized for your company’s unique needs. Give Tecafine Conduit Pipe Spacer a call today and one of our experts will answer all of your questions.

Duct Pipe Spacer

Tecafine Conduit Pipe Spacer is used to support, separate and electrically insulate a pipeline in the trench. Typical uses of Tecafine Conduit Pipe Spacer include Cable Ducts, water pipes and in telecommunication industry.

Technical Details

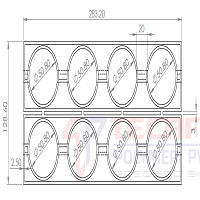

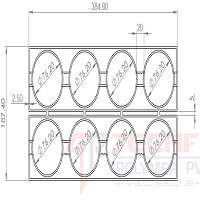

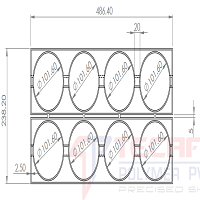

- Available Sizes – 100 mm to 250 mm

- Available Width – 10 mm to 50 mm

- High Compression Strength.

- Low Co-efficient of friction

- Tensile Strength ~5000-7500 psi

- High Impact Strength

- High Hardness Level

Product Features

- Uniform Support to Weight Of Pipe

- Weather resistance

- Chemical resistance

- Electrical Insulation

- Dimensional Stability

- Corrosion Protection

- Keeping various pipes pipe separate

- Precise dimensions

- Custom Made

- Best quality material used

Our range of pipe casing spacers / insulators centre water and sewer pipes in casings. They are used to support and electrically insulate a pipeline from a casing pipe through which it must pass. The spacers are easy to install, are virtually corrosion proof, and provide insulating protection from a possible electrical shorting between the carrier pipe and casing. No special tools are required and they are easily applied by a single worker. The casing spacers eliminate the need to fill the casing annulus with sand and as they are so easy to remove, it allows damaged pipes to be repaired or replaced quickly. Let us know what your required runner height is (annular clearance between the inner pipe and the outer casing) and we will offer you a suitable solution for your pipeline.

Spacers are designed to support and cradle conduit for ease of installation, allowing optimal free flow of grout, thereby eliminating voids. Bore Spacers also maintain accurate duct position and alignment that will result in a reduction of installation time, isolation, boosting efficiency and ensuring that the installation is performed correctly. Features include:

- Multiple conduit sizes and designs

- Accommodates any type conduit or casing pipe

- Conduit to conduit separation to customer specification

- HDPE or polypropylene wheels with steel axle

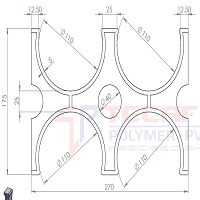

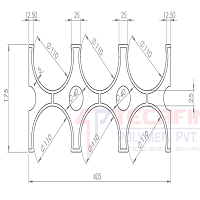

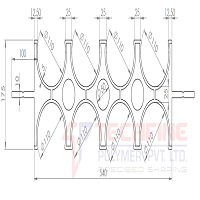

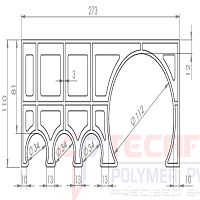

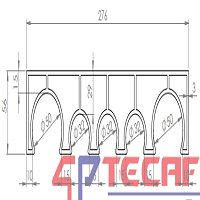

Drawings

Spacers

Spacers assist in installation of the piping system. We recommend that a spacer be used in each horizontal and vertical run of piping to adjust for dimensional piping differences. Spacers are available as filler flanges and ring spacers. Spacers can be machined in the field during system fit-up. This is important for existing piping systems where dimensions may have changed due to settling of foundations over the years.

Filler flanges are full face with drilled bolt holes and spiral groove phonographic finish on both sides for a good gasket surface. They match the pipe inside diameter and flange outside diameter. They are available in sizes 3″ through 30″ and thickness as required for system. We maintain a stock of 1/2″, 1″, 2″ and 3 ½” thick filler flanges in the different pipe sizes.

During field fit-up, tapered filler flanges can be used if mating flanges are not parallel.

Ring spacers match the pipe inside diameter and fit inside the flange bolt circle. They are available in 3″ through 30″ sizes in specific thicknesses or in a standard 12″ length. The standard 12″ length can be cut to the required thickness and machined with a gasket surface.